S4 PPDS Course Details

SAP S/4HANA PP/DS Online Training at GreenByte Technologies

Introduction to SAP S/4HANA PP/DS (Production Planning and Detailed Scheduling)

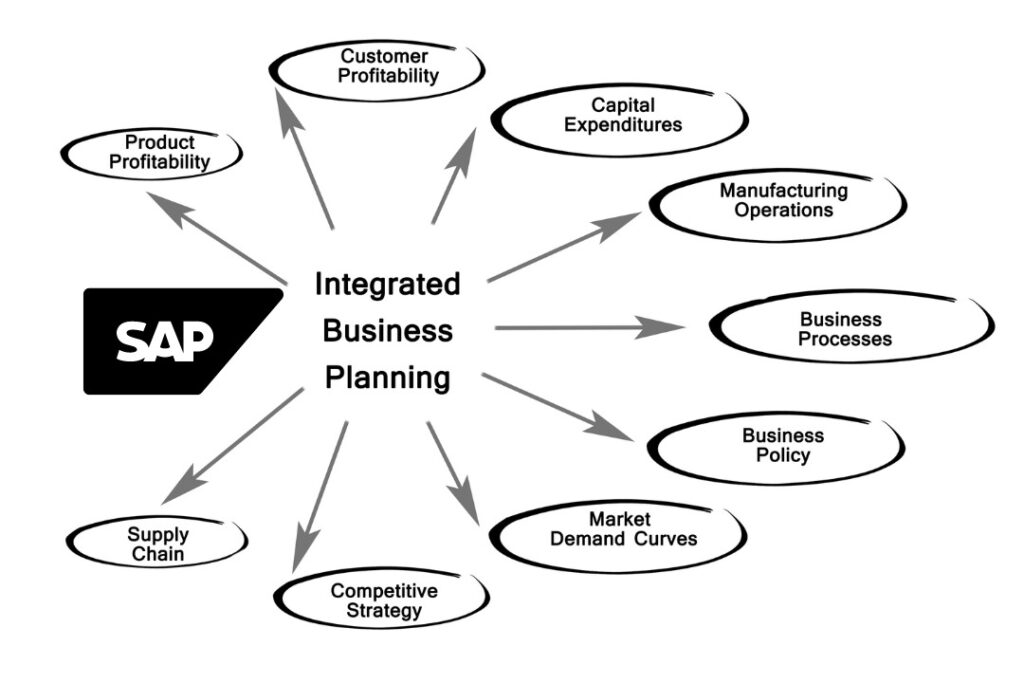

SAP S/4HANA Production Planning and Detailed Scheduling (PP/DS) is a vital module within the SAP ERP framework that enables businesses to optimize their production processes and detailed scheduling. PP/DS is an advanced planning tool that helps in managing production planning, capacity planning, and scheduling in a highly efficient manner. At GreenByte Technologies, the SAP S/4HANA PP/DS online training course provides comprehensive insights into leveraging this powerful tool to meet business objectives.

Course Overview

The SAP S/4HANA PP/DS online training at GreenByte Technologies is designed to equip participants with the knowledge and skills needed to effectively use SAP's advanced planning capabilities. This training covers various aspects of production planning, from the basics to the more complex functionalities, enabling participants to manage and optimize production processes.

Key Features of the Training

-

Comprehensive Curriculum

The course covers all aspects of SAP S/4HANA PP/DS, including master data management, demand planning, production planning, detailed scheduling, and integration with other SAP modules. -

Expert Trainers

GreenByte Technologies boasts a team of expert trainers with extensive industry experience in SAP S/4HANA PP/DS. They provide practical insights and hands-on training to ensure that participants can apply the concepts in real-world scenarios. -

Flexible Learning

The online training format allows participants to learn at their own pace, with access to recorded sessions, interactive live sessions, and a wealth of learning resources. -

Hands-on Experience

The training includes practical exercises and case studies to help participants gain hands-on experience with SAP S/4HANA PP/DS.

Benefits of SAP S/4HANA PP/DS Training

-

Enhanced Planning Efficiency

By mastering SAP S/4HANA PP/DS, participants can significantly improve their organization's production planning efficiency. The training provides the tools and techniques needed to optimize production schedules, reduce lead times, and increase overall productivity. -

Improved Decision-Making

The advanced analytical capabilities of SAP S/4HANA PP/DS enable participants to make informed decisions based on real-time data. This results in better resource utilization, cost savings, and improved customer satisfaction. -

Career Advancement

Professionals with expertise in SAP S/4HANA PP/DS are in high demand in the job market. This training equips participants with valuable skills that enhance their career prospects and open up new opportunities in the field of supply chain management. -

Hands-on Experience with Industry-Leading Tools

The practical exercises and case studies included in the training provide participants with hands-on experience in using SAP S/4HANA PP/DS. This helps them gain confidence in applying their knowledge to real-world scenarios.

Why Choose GreenByte Technologies for SAP S/4HANA PP/DS Training?

-

Proven Track Record

GreenByte Technologies has a proven track record of delivering high-quality SAP training to thousands of professionals worldwide. Their training programs are designed to meet the needs of both beginners and experienced professionals. -

Customized Learning Paths

The training is tailored to the specific needs of participants, with flexible learning paths that allow them to focus on areas that are most relevant to their career goals. -

Comprehensive Support

GreenByte Technologies provides comprehensive support to participants throughout their learning journey. This includes access to learning resources, mentoring from expert trainers, and assistance with certification exams.

S4 PPDS Curriculum

S4 PPDS Faq’s

S4 PPDS Reviews

S4 PPDS rated (5.0 / 5) based on 2 reviews.Ravi Kiran T

The SAP S4 PPDS course at GreenByte Technologies was a great experience. The trainer was highly knowledgeable and explained everything in detail. His clear explanations and dedication to student success were evident throughout the course, making complex concepts easy to understand. I would highly recommend this course for anyone looking to gain expertise in SAP S4 PPDS.

Aravind D

I had an excellent experience with the SAP S4 PPDS course at GreenByte Technologies. The curriculum was thorough, and the practical labs were especially valuable for understanding real-world applications. The course was well-structured, and the support from the faculty was commendable. It was truly worth every penny! Highly recommended for anyone serious about mastering SAP S4 PPDS.