SAP IBP Response and Supply, Inventory Optimization Course Details

SAP IBP Response and Supply, Inventory Optimization Online Training in India at GreenByte Technologies

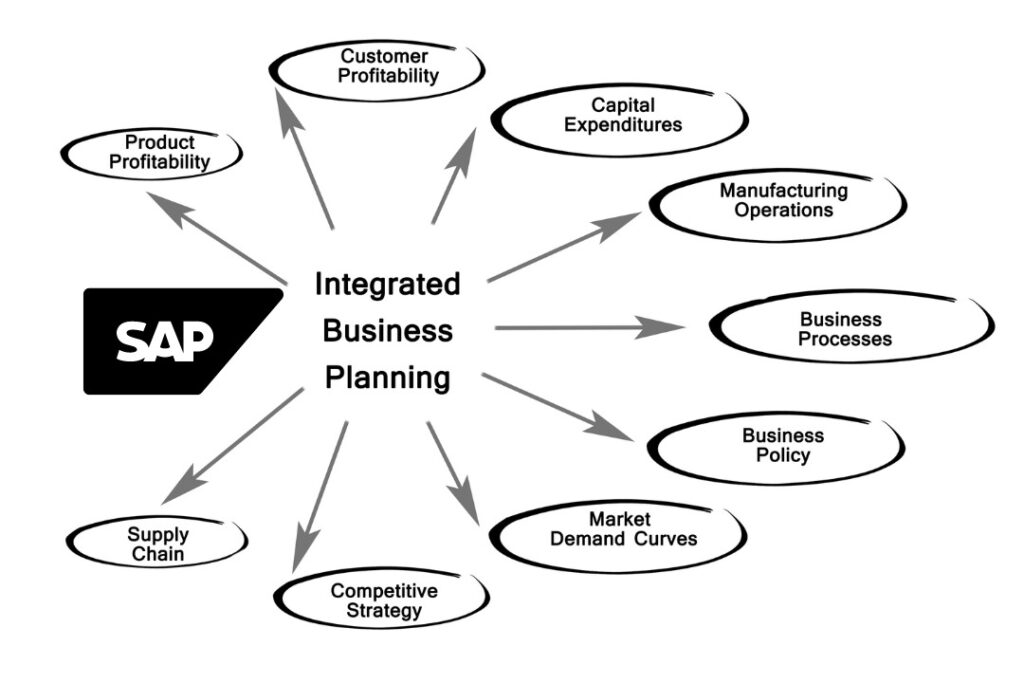

In today’s competitive business landscape, efficient supply chain management is paramount for organizations striving to stay ahead. SAP Integrated Business Planning (IBP) is a powerful tool that provides advanced capabilities for managing various aspects of supply chains. Among its modules, Response and Supply and Inventory Optimization play critical roles in ensuring operational efficiency and profitability. GreenByte Technologies, a leading training institute in India, offers comprehensive online training in these areas, equipping professionals with the skills to leverage SAP IBP for supply chain success.

Understanding SAP IBP Response and Supply

SAP IBP for Response and Supply is a module designed to address the complexities of supply chain responsiveness and operational efficiency. It facilitates real-time visibility into supply chain operations, enabling businesses to respond quickly to changes in demand and supply.

Key Features of SAP IBP Response and Supply

-

Real-time Visibility:

- Provides end-to-end visibility into the supply chain.

- Identifies bottlenecks and inefficiencies in real time.

-

Demand-Supply Balancing:

- Synchronizes supply plans with fluctuating demand patterns.

- Optimizes production schedules and inventory levels.

-

What-If Analysis:

- Simulates scenarios to assess the impact of different supply chain strategies.

- Enables informed decision-making for better outcomes.

-

Collaboration Across Teams:

- Facilitates collaboration between procurement, manufacturing, and distribution teams.

- Aligns planning processes across the organization.

-

Advanced Algorithms:

- Uses optimization techniques for resource allocation and planning.

- Minimizes costs while maintaining service levels.

Importance of SAP IBP Inventory Optimization

Inventory Optimization within SAP IBP focuses on maintaining the right inventory levels to meet customer demand while minimizing carrying costs. It is a crucial component for businesses looking to reduce waste and improve profitability.

Key Features of SAP IBP Inventory Optimization

-

Multi-Echelon Inventory Optimization (MEIO):

- Optimizes inventory across multiple levels of the supply chain.

- Ensures balanced stock levels to prevent shortages or overstocking.

-

Safety Stock Planning:

- Calculates optimal safety stock levels based on demand variability.

- Helps maintain consistent service levels.

-

Dynamic Replenishment:

- Adapts replenishment strategies to real-time changes in demand and supply.

- Reduces the risk of stockouts and excess inventory.

-

Cost-Effective Strategies:

- Balances inventory costs against service level goals.

- Maximizes return on investment in inventory management.

-

Integration with Other Modules:

- Works seamlessly with SAP IBP Demand and Supply Planning modules.

- Provides a unified platform for inventory and supply chain management.

About GreenByte Technologies

GreenByte Technologies is one of the premier training institutes in India specializing in SAP technologies. With a focus on delivering practical and industry-relevant training, GreenByte has built a reputation for excellence. The institute offers online training programs that cater to the needs of professionals seeking to enhance their skills in SAP IBP, including the specialized areas of Response and Supply and Inventory Optimization.

Why Choose GreenByte Technologies?

-

Expert Trainers:

- Highly experienced trainers with real-world expertise in SAP IBP.

- In-depth knowledge of industry best practices and trends.

-

Comprehensive Curriculum:

- Covers all aspects of SAP IBP Response and Supply and Inventory Optimization.

- Includes hands-on exercises and practical case studies.

-

Flexible Learning Options:

- Online training accessible from anywhere.

- Flexible schedules to accommodate working professionals.

-

Industry-Relevant Projects:

- Real-world projects to ensure practical understanding.

- Helps participants gain confidence in applying learned concepts.

-

Placement Assistance:

- Dedicated support for job placement and career guidance.

- Strong network of industry connections.

SAP IBP: Response and Supply Planning & Inventory Optimization

SAP Integrated Business Planning (IBP) is an advanced cloud-based solution for end-to-end supply chain management. The Response and Supply Planning and Inventory Optimization components are vital for organizations aiming to balance supply, meet customer demands efficiently, and minimize inventory costs.

Response and Supply Planning

The Response and Supply Planning module is a dynamic and flexible solution designed to align supply with demand at the most granular level. It enables businesses to respond rapidly to changes in customer demand and supply constraints while considering real-world limitations.

Core Features

-

Order-Based Planning (OBP):

- Focuses on individual orders, such as sales orders and stock transfer orders.

- Ensures precise supply chain alignment at the order level.

-

Real-Time Planning:

- Allows for immediate reaction to demand and supply changes.

- Uses up-to-date data to generate actionable plans.

-

Scenario Planning:

- Enables "what-if" analysis for potential disruptions or demand shifts.

- Facilitates decision-making based on simulated outcomes.

-

Constraint-Based Planning:

- Considers production, transportation, and storage capacity constraints.

- Optimizes resource allocation while adhering to business rules.

-

Global Visibility:

- Provides an end-to-end view of the supply chain.

- Integrates with external systems like SAP S/4HANA for real-time updates.

Key Benefits

- Improves customer satisfaction by meeting demand promptly.

- Increases agility in responding to disruptions and market changes.

- Reduces unnecessary inventory buildup and associated costs.

- Streamlines collaboration across supply chain stakeholders.

Applications in Business

- Managing last-minute order changes.

- Allocating limited supplies based on predefined priorities.

- Balancing short-term demand spikes with existing resources.

Inventory Optimization

The Inventory Optimization module focuses on reducing inventory costs while maintaining service levels. It achieves this by leveraging advanced analytics to calculate optimal stock levels across all supply chain nodes.

Core Features

-

Multi-Echelon Inventory Optimization (MEIO):

- Balances inventory across multiple storage and distribution points.

- Reduces excess inventory at specific locations while ensuring availability.

-

Safety Stock Calculation:

- Uses demand and supply variability to determine the right amount of safety stock.

- Ensures readiness for unexpected demand changes.

-

Service Level Management:

- Aligns inventory strategies with customer service goals.

- Helps achieve target service levels without overstocking.

-

Inventory Segmentation:

- Categorizes inventory by importance (e.g., ABC analysis).

- Applies differentiated strategies to critical and non-critical items.

-

Cost Optimization:

- Minimizes carrying costs, obsolescence, and stockouts.

- Factors in penalties for late delivery or unmet demand.

Key Benefits

- Reduces working capital tied up in inventory.

- Improves supply chain efficiency through balanced stock levels.

- Enhances customer satisfaction by avoiding stockouts.

- Mitigates risks of excess or obsolete inventory.

Applications in Business

- Optimizing stock levels for seasonal products.

- Minimizing costs while maintaining readiness for emergencies.

- Aligning inventory plans with demand forecasts.

Integration Between Response and Supply Planning and Inventory Optimization

The integration of Response and Supply Planning and Inventory Optimization creates a seamless approach to managing supply chains:

-

Real-Time Adjustments:

- Inventory Optimization sets the baseline for stock levels, while Response and Supply Planning dynamically adjusts to real-time changes in demand and supply.

-

End-to-End Visibility:

- Both modules share data, ensuring consistent decision-making across planning and execution levels.

-

Strategic Alignment:

- Ensures that operational inventory decisions align with broader supply chain strategies.

-

Resilience Building:

- By optimizing inventory levels and dynamically responding to disruptions, businesses can maintain service levels and cost-efficiency during unpredictable events.

Use Cases and Benefits

-

High-Tech and Electronics:

- Quickly respond to changing customer orders while keeping minimal inventory.

- Optimize inventory for new product launches.

-

Retail and Consumer Goods:

- Manage seasonal fluctuations with precision.

- Ensure optimal stock placement across multiple locations.

-

Pharmaceuticals:

- Maintain critical inventory for high-priority items.

- Meet regulatory requirements for stock levels.

SAP IBP Response and Supply, Inventory Optimization Curriculum

SAP IBP Response and Supply, Inventory Optimization Faq’s

SAP IBP Response and Supply, Inventory Optimization Reviews

SAP IBP Response and Supply, Inventory Optimization rated (4.7 / 5) based on 3 reviews.Ramachandran

I have joined the SAP IBP Response and Supply, Inventory Optimization Course online at GreenByte Technologies, and I must say, the trainer is exceptional. He explains everything in great depth, combining theory with practical examples and providing comprehensive notes. What stands out the most is his dedication to addressing and clearing doubts, which is particularly valuable for online students like me, where resolving queries can sometimes be challenging. Overall, it has been a fantastic learning experience.

Srujan Rao

I wanted to specialize in inventory optimization, and this course was perfect. The MEIO module was particularly helpful in improving my organization's inventory practices.

Devi Arjun

GreenByte Technologies provided a comprehensive learning experience. The flexible schedule allowed me to balance my work and studies, and I cleared the SAP IBP certification on my first attempt.